CGD & Reverse Engineering

Application

Due to Tyne Engineering’s broad scope of experience in design, manufacturing, and testing to stringent Quality levels in the nuclear field, in areas of tritium handling, pressure vessels/pressure piping, and instrumentation and control, we are ideally suited as a supplier for Commercial Grade Dedication Services including design, reverse engineering, qualifiction, and manufacturing.

Features

-

In-house manufacturing and modification of process modules, gloveboxes, instrumentation and control systems, cable harnesses, pressure vessels.

-

Audited by CANDU Procurement Audit Committee (CANPAC) to CSA Z299.1 and N286 makes Tyne suitable for safety-related Commercial Grade Dedication work for the nuclear field.

-

ASME sec III, sec VIII div 1, B31.1 and B31.3 pressure vessels and piping (TSSA certified to N285.0)

-

ISO9001:2000

-

Extensive design, drafting and documentation capabilities

-

Broad scope of engineering disciplines.

Description

Techniques employed in Commercial Grade Dedication and Reverse Engineering include all manner of design, drafting, and documentation, including those applicable to the nuclear industry. We have a complete series of documents prepared in house. Design work we have undertaken includes conceptual and developmental designs as well as detailed implementation of known process designs and mechanical equipment designs.

We developed our own QA procedures and manuals, certified to ISO 9001:2000, which meet the needs of an extensive work scope of design through manufacturing and operation. We have been successfully audited by COG (through CANPAC) to CSA Z299.2, and by AECL to the same level. Tyne is an excellent choice for Commercial Grade Dedication for nuclear work as well as Reverse Engineering in the nuclear field..

To extend our certification further we have also been approved independently by TSSA to design, build and repair Piping systems and Pressure Vessels to ASME VIII Div 1 and B31.3. TSSA certification applies to work in our own offices and off site repair work.

As we are often involved in Research & Development, we have had our QA manual extended to also include R&D. This provides us with the facility to make or develop new components or subcomponents as needed.

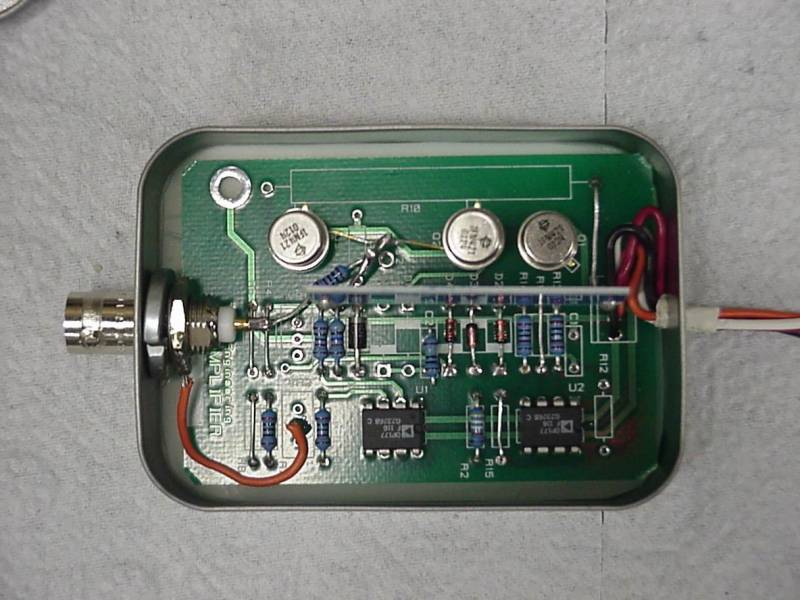

Signal processor and display unit - redesign and manufacture of circuit boards

Tyne Engineering has mechanical, electrical and C&I capability. We design build and program touch screen kiosks for multipurpose use; we have manufactured totally automated computer controlled systems which have run and continue to run with minimal intervention in laboratory and plant environments, some for many years.

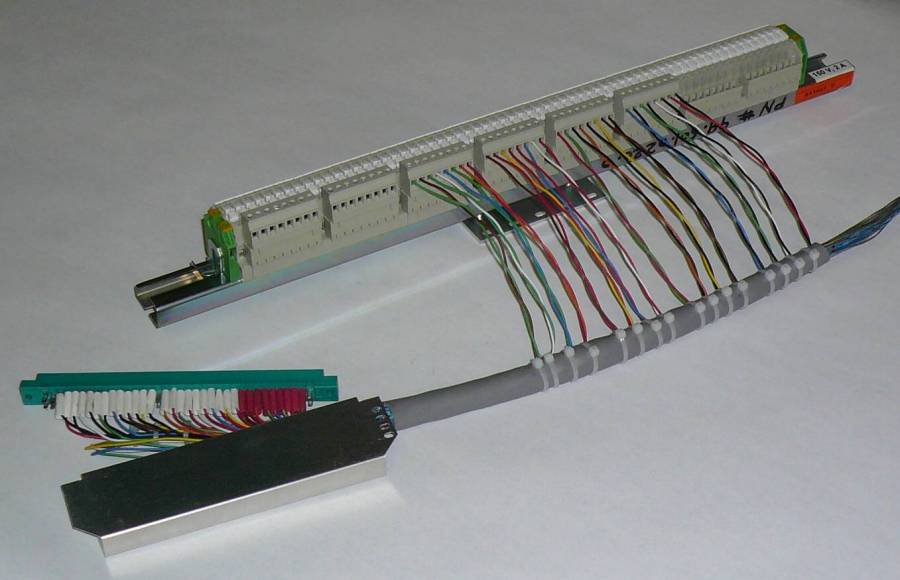

Tyne has manufactured updated nuclear plant control cable assemblies as replacements for existing assemblies which were damaged by exposure to radiation.

Modification and replacement of radiation-damaged components

We have also designed and built systems which implement complicated electronic circuit boards, associated components, and require custom computer programs – all done in house. These projects frequently involve stringent Quality Control requirements of nuclear plant and nuclear research laboratories.

Modification of designs to include currently available components

Having manufactured and refurbished nuclear stack monitoring equipment, we are also well versed in the environmental restrictions imposed on our customers.

Tyne has considerable project management experience proven in all aspects of work from contract initiation and review through design, procurement using our own approved vendors list, through manufacturing, testing and commissioning on a variety of projects.

Tyne Engineering's unique experience in the fusion industry provides us with wide and unique capability that lends itself ideally to work associated with modification of outdated or unavailable equipment. Our ability to contribute is enhanced both from our understanding of the requirements and our ability to turn this into manufacturing reality.

Tyne has approved welders on staff. They perform to Tyne's approved welding procedures in TIG, stick, and stud welding. We also have procedures developed for our automatic tube welding and can carry this out to our approved welding procedures.

We also have helium leak testing capability and have equipment and personnel trained and equipped to carry out helium leak testing to 1 x 10E-9 atm. cc/s. Also through established relationships with our partners, we can claim full NDE capability and manufacturing capability.

Tyne is familiar with high and ultra high vacuum systems, having designed and built and participated in this technology for many years. We are familiar with LN2 and He cryogenics, having designed and built equipment employing cryotraps and other functions; we make getter beds utilizing our license for carrying depleted uranium and we also manufacture some small test sources including americium 241, and amorphous silicon-bound tritium sources.

Our company is also familiar with high pressure design, having designed and manufactured vessels that operate up to 600 psig, and high temperatures up to 1000°C as was the case in a combustion chamber/oxidizer which we built for Ontario Hydro.

We design and build instruments such as tritium monitors which we have sold in Korea, China, England, USA etc. We have designed and modified vacuum pumping equipment and are familiar with the operation construction and performance of many and varied pumps and blowers, heat exchangers, and boilers. We have designed, built and successfully operated recombiners (oxygen and hydrogen), condensers, chillers, chemical reactors, molecular sieve driers, cryogenic distillation equipment, distillation columns, cryotraps, etc.

In keeping with our QA procedures every project is given a project number and starts with the preparation of a Project Plan, which calls up and references other plans as needed including Design Plan, Manufacturing Plan, QA Plan, R&D Plan as necessary to ensure that each project is approached and managed according to its needs. This always proceeds within the structure of our QA program.

For detailed information, please request Doc# 7.5.1.4 “Tyne’s Approach to Commercial Grade Dedication”

A brief summary of Tyne's approach to Reverse Engineering and Commercial Grade Dedication (CGD) is as follows:

Evaluation of current component needs

By review of existing documentation, and assessment of the requirements of components and clients, we arrive at the fundamental needs and critical characteristics of each component including the level of QA which is needed.

Assessing availability of component parts

We review and assess existing suppliers of parts, establish their ability to provide replacement parts and create or modify documentation such as specifications to control the supplies. Through this assessment a complete bill of materials can be created to meet a particular component's requirements

Classification of components

We evaluate NDE requirements, material compositions, and code application. Authority approvals are obtained where applicable. We carry out Failure Modes and Effects Analysis (FMEA) and create Mean Time Before Failure (MTBF) records for the parts.

We use our resources to give confidence that components will fully meet their intended use; that they can be acquired with high reliability and reasonable cost; and that there is high probability of future availability.

Tyne Engineering is ideally suited to the work of Reverse Engineering or Commercial Grade Dedication, and will endeavor to ensure that above requirements are tailored to a Client's needs and programs giving close attention to costs and schedules.